inventory

2024-08-29 11:53:51 0 Report

Login to view full content

Other creations by the author

Outline/Content

The basic types of inventory

raw material inventory

Classified by type of material

Metal raw materials

non-metal raw materials

Categorized by storage conditions

Room temperature storage

Cold storage

Finished goods inventory

Categorize by product series

Electronics series

Home Goods Series

Categorized by sales channel

Online sales inventory

Offline sales inventory

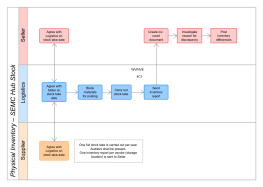

Inventory management strategy

Inventory control method

Regular inventory method

Monthly inventory check

Quarterly review

Safety Stock Method

Set the minimum inventory level

Dynamically adjust inventory levels

Inventory optimization strategy

Reduce inventory backlog

Promotional clearance sale

Product upgrade and iteration

Improve inventory turnover rate

Optimize the supply chain process

Strengthen sales forecasting

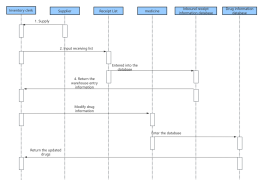

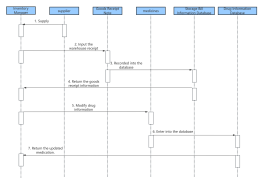

Information management of inventory

Inventory Management System

System Function Introduction

Stock Management

Output: Outbound Management

Inventory Inquiry

System implementation steps

requirement analysis

System selection

Training上线

Inventory data analysis

Inventory Turnover Analysis

Monthly turnover rate

Annual turnover rate

Inventory cost analysis

Procurement cost

Holding cost

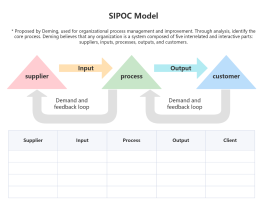

The definition of inventory

Inventory is one of the largest and most important assets a company owns. It refers to goods, items, commodities, and parts that are for sale, as well as raw materials used in production or for repairing products to generate profit.

The purpose of inventory

I. Effective Utilization of Capital

Prevent capital stagnation: avoid long-term backlog of excess materials and ensure that funds can circulate in a virtuous cycle to generate profits.

II. Ensure the smoothness of sales and production

Maintain the minimum inventory level: Ensure that sales flow can proceed smoothly, with the inventory of products reaching the minimum limit that does not lead to insufficient stock, avoiding the accumulation of capital.

Promote production: Inventory serves as an important means to ensure material supply during the production period, which helps to reduce the rate of material shortage and promote the continuity and stability of production.

III. Respond promptly to market changes

Master inventory status: By monitoring inventory in real-time, companies can adjust production and sales plans promptly to avoid overproduction or shortages.

Adapt flexibly to market demands: In a fiercely competitive market environment, efficient inventory management enables enterprises to respond quickly to changes in market demand, providing stable and timely supply services, thereby increasing customer satisfaction and market share.

IV. Reduce Operating Costs

Save on inventory costs: Properly maintaining inventory levels can save on storage expenses, alleviate financial pressure, and improve operational efficiency.

Optimize resource allocation: Through reasonable inventory planning, companies can avoid resource waste, ensure the smooth progress of production and sales, thereby reducing overall operating costs.

V. Achieve sustainable development

Reducing resource waste: Reasonable inventory management helps to reduce resource waste and environmental pollution, aligning with the concept of sustainable development.

Optimize the supply chain: By optimizing the supply chain and procurement strategies, companies can reduce carbon emissions and energy consumption, contributing to the construction of a green, low-carbon future.

Collect

Collect

Collect

Collect

Collect

0 Comments

Next page

Recommended for you

More